| Arjun Technologies: 2D to 3D with Autodesk Inventor |

| Written by Machinist | |

| Thursday, 13 December 2007 | |

|

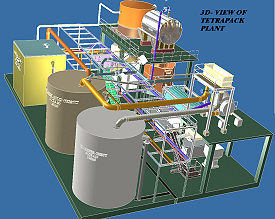

Customer Profile: Arjun Technologies is a medium sized Engineering company undertaking supply of process plants for the pulp and paper industry. With more than one decade in the paper industry Arjun Technologies India Limited (ATIL), the Indian arm of C P Engineering GmbH has emerged as the leading turnkey system supplier in the Indian Paper Industry. Business Situation: As a part of their projects, they undertake extensive design and engineering of these process plants. They develop complete P & IDs, equipment layouts, piping layouts, cable tray routings, and etc. for these process plants and also component drawings for their manufacture. They had been using a 2D platform for a decade and there were many issues with it. The biggest challenges faced while using 2D solution were: * Increase productivity * Reduce human errors Solution: Using Inventor 11.0 3D software to overcome the bottlenecks in AutoCAD and to improve their design productivity Benefits: * Significant increase in productivity since moving from 2D to 3D with Inventor 11.0 * Better modeling capabilities; 3D mpeg visualization for better understanding and also for product demonstration * Reduction in errors * Increasing product quality  From raw material handling to pulp mill to paper machinery accessories to converting to materials handling, Arjun Technologies has grown to be the One-Stop-Shop for the paper Industry. From raw material handling to pulp mill to paper machinery accessories to converting to materials handling, Arjun Technologies has grown to be the One-Stop-Shop for the paper Industry. They brought together the best expertise and experience from some of the world's forerunners in pulp and paper machinery manufacturing. With a professional and understanding approach to project feasibility, planning and management alike, Arjun Technologies India has provided value added engineering services from concept through commissioning. ATIL has executed more than 30 projects in India, South Asia, South-East Asia, the Middle East; these include projects funded by multinational funding institutions like the World Bank, Asian Development Bank etc. and a bilateral funding institution like Overseas Economic Cooperation Fund (OECF). As a part of their projects, they undertake extensive design and engineering of these process plants. They develop complete P & IDs, equipment layouts, piping layouts, cable tray routings, and etc. for these process plants and also component drawings for their manufacturer. Autodesk, the world's leading software and services company, offered Autodesk Inventor 11.0 that helped creating 3D equipment and piping layouts reducing the project completion time dramatically, provided them with a holistic visualisation of plants at the early design stages and eliminated the chances of human errors. Situation  Arjun Technologies is a medium-sized engineering company supplying process plants for the pulp and paper industries. They undertake extensive design and engineering of process plants for which they develop complete equipment and piping layouts as well as cable tray routings. Arjun Technologies is a medium-sized engineering company supplying process plants for the pulp and paper industries. They undertake extensive design and engineering of process plants for which they develop complete equipment and piping layouts as well as cable tray routings. Using a 2D software platform for a decade, they confronted numerous challenges; the biggest of which was that in a multi-user environment there were always chances of human errors. The designs that they used here are inter-disciplinary including civil, architectural, piping and mechanical design. These engineering designs have to follow a sequence. For instance, every change incorporated had to be done in a sequence. The challenge they faced with 2D design software was the lack of interlinking of drawing sequences leading to a lot of human errors. Thus, if a change was not incorporated in one drawing sequence, it did not reflect in the subsequent ones, leading to inaccurate production. This process was extremely time consuming, resulting in the slowing down of the project lifecycle. Additionally, revision and updation was being too ambitious on 2D. Visualisation of the end product was not viable since the product simulation features were not available on the software. Moving on to 3D Identifying these bottlenecks amplified their need to upgrade the design productivity platform inorder to communicate and manage design data, enable faster production and optimise workflow; eliminating the possibility of human errors. In short, aiming at a short and precise design cycle they looked for a solution that would improve productivity and embarked upon a program to upgrade design facilities to a 3D environment. They decided to choose Autodesk Inventor 11.0 as they had been using the company’s AutoCAD product for many years. To begin with, they took two licences of Inventor 11.0 in order to evaluate the product for a year. The shift from 2D to 3D was a gradual one, as the engineers were not trained on the 3D platform. Autodesk installed the software and provided requisite training which gave adequate momentum to the migration process. They have now decided that all new product development will be done on Inventor 11.0. The switchover is complete and they are currently using nine user licenses of Inventor 11.0. The implementation was completed in August 2005 and their design engineers are thoroughly trained on the new platform. Where Autodesk Inventor 11.0 scores Autodesk Inventor helped them to reduce the project completion time and now changes can be incorporated in a design sequence almost immediately. There is ease of visualisation at the preliminary stages of designing which enables product demos possible at appropriate times. It is also feasible to check the interface of pipes thoroughly in a virtual environment using the 3D platform. Benefits * Minimal human errors as changes are immediately reflected in the other drawing sequences of a project. * The project completion time has drastically reduced as changes can be incorporated in a design sequence almost immediately. * Better visualisation gives a better idea of how the plant will look upon completion. * Better modelling capabilities. “By moving from 2D to 3D, there are fewer design errors while developing detailed, production-ready designs. We are able to store and manage all designs from a central location that can be accessed by our design teams” - Mr. S. Soundarajan, General Manager, Projects and Engineering, Arjun Technologies. |

|

| Last Updated ( Thursday, 13 December 2007 ) |

| Earlier on |